|

What is ISO 9001:2015 – Quality management systems?

001 is the international standard that specifies requirements for a

quality management system (QMS). Organizations use the standard to

demonstrate the ability to consistently provide products and services that

meet customer and regulatory requirements. It is the most popular standard

in the

ISO 9000 series and the only standard in the series to which

organizations can certify.

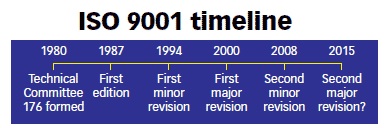

ISO 9001 was first published in 1987 by the International Organization

for Standardization (ISO), an international agency composed of the

national standards bodies of more than 160 countries. The current version

of ISO 9001 was released in September 2015.

Who should use the ISO 9001:2015 – quality management

systems revision?

ISO 9001:2015 applies to any organization, regardless of size or

industry. More than one million organizations from more than 160 countries

have applied the ISO 9001 standard requirements to their quality

management systems.

Organizations of all types and sizes find that using the ISO 9001

standard helps them:

| Organize processes |

| Improve the efficiency of processes |

| Continually improve |

All organizations that use ISO 9001 are encouraged to transition to ISO

9001:2015 as soon as possible. This includes not only organizations that

are certified to ISO 9001:2008, but also any organizations involved in

training or certifying others.

Guidance on transitioning to ISO 9001:2015 can be

downloaded from the International Accreditation Forum (IAF).

What topics does ISO 9001:2015 cover?

ISO 9001 is based on the plan-do-check-act methodology and provides a

process-oriented approach to documenting and reviewing the structure,

responsibilities, and procedures required to achieve effective quality

management in an organization. Specific sections of the standard contain

information on topics such as:

| Requirements for a quality management system, including

documentation of a quality manual, document control, and determining

process interactions |

| Responsibilities of management |

| Management of resources, including human resources and an

organization’s work environment |

| Product realization, including the steps from design to delivery

|

| Measurement, analysis, and improvement of the QMS through activities

like internal audits and corrective and preventive action |

Looking for a longer introduction to the ISO 9001 standard and the

process approach?

Read these popular open-access articles from QP magazine:

ISO 9001 Made Easy

The Process Approach to QMS in ISO 9001 and 9004

Changes introduced in the 2015 revision are intended to ensure that ISO

9001 continues to adapt to the changing environments in which

organizations operate. Some of the key updates in ISO 9001:2015 include

the introduction of new terminology, restructuring some of the

information, an emphasis on risk-based thinking to enhance the application

of the process approach, improved applicability for services, and

increased leadership requirements.

See a collection of

featured resources providing more details on ISO 9001, including

materials you can use to prepare for the transition to ISO 9001:2015.

How do I get started with ISO 9001:2015?

Organizations and individuals that use ISO 9001 are encouraged to

transition to the 2015 revision as soon as possible. However, the

International Accreditation Forum (IAF) and the ISO Committee on

Conformity Assessment (CASCO) have agreed to a three-year transition

period from the publication date of ISO 9001:2015.

Whether you are beginning your ISO 9001 journey or transitioning to the

2015 revision, your first step is to

purchase a copy of ISO 9001:2015.

What are the benefits of ISO 9001?

ISO 9001 helps organizations ensure their customers consistently

receive high quality products and services, which in turn brings many

benefits, including satisfied customers, management, and employees.

Because ISO 9001 specifies the requirements for an effective quality

management system, organizations find that using the standard helps them:

| Organize a QMS |

| Create satisfied customers, management, and employees |

| Continually improve |

"It has been my experience, with several companies, that the culture

change associated with ISO implementation is multilayered. The first and

most obvious benefit is quality awareness," ASQ senior member Bud Salsbury

writes on

ASQ’s Ask the Experts blog. "This quality awareness does not fade away

easily. Even those who offer strong resistance to change learn to respect

and very much appreciate all the practical value in a good quality

management system."

ISO 9001 also provides financial benefits, such as cost savings.

In Nevada, the

Clark County School District used ISO 9001 to save $174 million over

10 years in actual expenditures and cost avoidance. More than 3,000

employees were trained to the standard, enabling three critical components

of the system’s success: training, communication and respect, and

efficiency.

Read other

ISO 9001 case studies to see the performance benefits of using the

standard.

ISO 9001:2015 as a “business management tool”

In an article for ASQ’s

QP magazine,

Oscar Combs summarizes results of a Harvard Business School study

comparing 916 organizations that have adopted ISO 9001 and 17,849

non-adopters. As Combs explains, the “business benefits” enjoyed by the

ISO 9001 organizations included higher rates of survival and growth,

increased wages, reduced waste, enhanced productivity, and improved health

and safety performance.

“ISO 9001 offers more than quality benefits. The standard should be

thought of as a business management tool an organization can use to

drive value, improve its operations and reduce its risks.”

- Oscar Combs,

Standard Wise

Achieving ISO 9001 certification

ISO 9001 is the only standard in the ISO 9000 series to which

organizations can certify. Achieving certification means that an

organization has demonstrated the following:

| Follows the guidelines of the ISO 9001 standard |

| Fulfills its own requirements |

| Meets customer requirements and statutory and regulatory

requirements |

| Maintains documentation |

Certification to the ISO 9001 standard can enhance an organization’s

credibility by showing customers that its products and services meet

expectations. In some instances or in some industries, certification is

required or legally mandated.

The certification process includes implementing the requirements of ISO

9001:2015 and then completing a successful registrar’s audit confirming

the organization meets those requirements.

As Bill Aston explains in an Expert Answers column for ASQ’s QP

magazine, organizations should consider the following as they begin

preparing for an ISO 9001 quality management system certification:

| Registrar’s costs for ISO 9001 registration, surveillance and

recertification audits |

| Current level of conformance with ISO 9001 requirements |

| Amount of resources that the company will dedicate to this project

for development and implementation |

| Amount of support that will be required from a consultant and the

associated costs |

Read

"What’s the cost?" for a checklist you can use to assess the costs of

certifying to ISO 9001.

ASQ does not issue ISO 9001 certification.

"For many organizations, once certification is achieved, there is an

attitude that no more effort is needed to improve the QMS. Such an

attitude is contrary to both the explicit requirements of ISO 9001 and

its intent."

- Charles A. Cianfrani and John E. "Jack" West,

ISO 9001:2008 Explained & Expanded

Training in the ISO 9001 standard

Training can provide an opportunity to review the ISO 9001:2015

standard and apply quality management principles in a practice

environment.

Professionals responsible for developing, implementing, auditing, and

managing an ISO quality management system or quality professionals

interested in updating their documented ISO 9001-based QMS can take

ISO 9000 training

courses, which include courses focused on ISO 9001 and quality

management systems. Additionally, organizations looking to improve

employee performance and employees looking to continually improve will

also find ISO 9000 training relevant.

Previous versions of ISO 9001

Originally published in 1987, ISO 9001 underwent revisions in 1994,

2000 and again in 2008. The latest revision was published in September

2015.

As John E. "Jack" West, Lorri Hunt, Nigel H. Croft, and Alka Jarvis

write in an article for

QP magazine:

| ISO 9001:1994 included changes to significantly improve the clause

on control of design and development, and to provide several other

clarifications. The 1994 series also slightly modified the role of ISO

9002 and 9003…. |

| The ISO 9001:2008 revision can be thought of as an amendment to

clarify issues that had been raised during the application of ISO

9001:2000. It included several changes to the text but no additional

requirements. |

Read an article in ASQ’s

QP magazine for details on the changes that took effect in

the revision from ISO 9001:2008 to ISO 9001:2015.

Organizations certified to the ISO 9001:2008 standard will have a

three-year period to transition to ISO 9001:2015. When the transition

period ends in September 2018, ISO 9001:2008 certificates will no longer

be valid. Organizations looking to start their transition to the 2015

revision can

purchase a copy of ISO 9001:2015.

Why did you look up ISO 9001:2015?

Please let us know what resources your organization needs to support

its ISO 9001 efforts. If you would like a reply, please include an email

address.

|